Bigger Barrel? No Problem

There are certain scenarios in which you may want to fit a bigger barrel into your AG Composites carbon fiber or fiberglass rifle stock was made for.

If you’re building a custom rifle, maybe you ordered the stock before the barrel, and you were uncertain of the barrel contour/dimensions. Maybe you want to re-barrel an existing rifle with a heavier (larger) barrel contour. Or, maybe you bought a barrel from a friend who didn’t know the contour and it’s just a little bigger than the barrel channel on your stock.

No matter the reason, don’t sweat it.

If the barrel channel only needs to be opened up a little – for example if the barrel fits in the channel but not without touching the stock – sandpaper and a dowel rod can be used. Hand sanding without a dowel works well, too.

Using 120 to 180 grit sandpaper, sand evenly on all surfaces where the barrel contacts the stock until you’ve opened the barrel channel enough that the barrel fits. The idea is to avoid contact between the stock and barrel for the full length of the stock.

Just a side note but: it’s not healthy to breathe carbon fiber dust, so we highly recommend wearing a dusk mask while sanding.

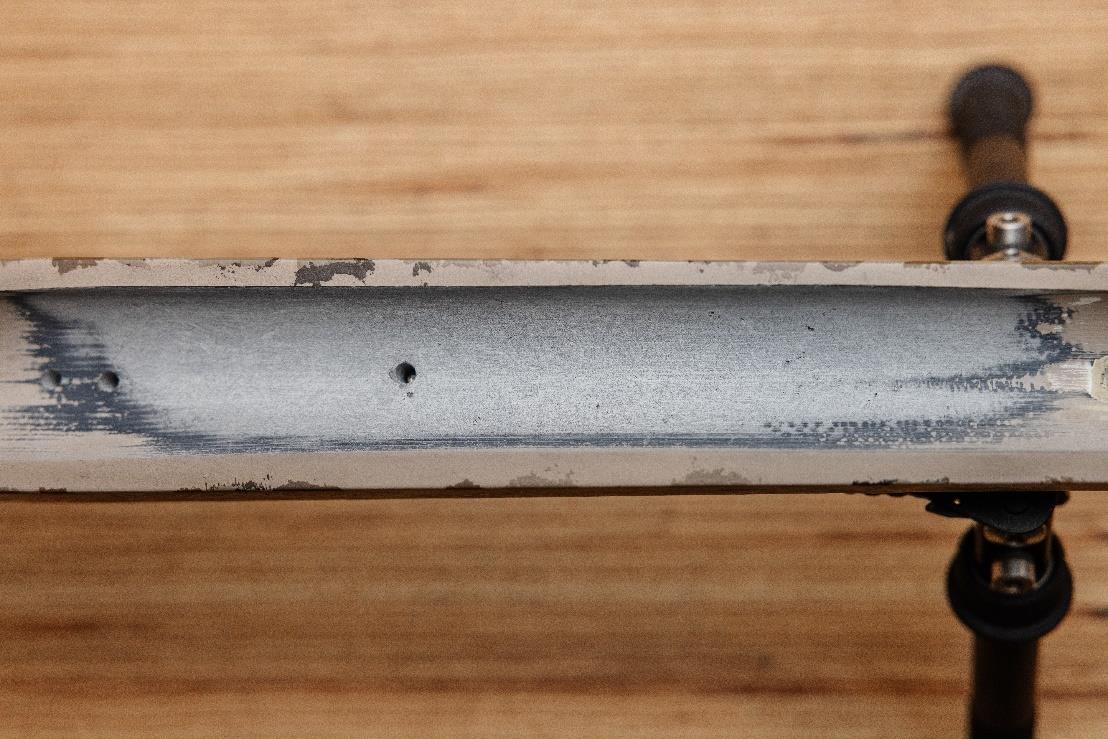

A good way to determine that there is no contact between the stock and barrel is to place the barreled action into the stock, install the bottom metal, torque the action screws to 55 to 65 inch-pounds, and slide a dollar bill between the stock and the barrel for the length of the barrel channel. It should pass between the two without catching anywhere.

A great way to determine if there is any contact between the barrel and the stock is to slide a dollar bill down the length of the barrel channel.

If greater modification is needed than what can be accomplished with sandpaper, you should contact a gunsmith. For example, if you want to change from a light steel barrel to a carbon barrel, using sandpaper would take hours and maintaining consistency for the length of the barrel inlet would be extremely difficult.

Once you or a gunsmith have opened the barrel channel to the desired size, understand that it’s not necessary to paint the barrel channel. The fill material used in AG Composites carbon fiber and fiberglass stocks is 100% impervious to weather.

After sanding or machining the barrel inlet, it’s not necessary to paint the exposed stock fill material.

Should you wish to paint the barrel channel anyhow, it will do no harm. Any high-quality automotive paint is fine. Just be certain that you’ve thoroughly removed any dust generated in the sanding process before paint is applied. A good way to do this is with an air compressor.

A word on barrel contours

All AG Composites stock models can accommodate barrel contours up to a 1.3” straight taper.

When you order a stock from the AG Composites website, a drop-down menu offers 32 different barrel contours from which to select. If your barrel contour is not listed, or if you don’t know your barrel contour, please call us to discuss it.

Some customers think that a barrel diagram is all that’s needed to make a new channel program (for a contour that isn’t listed on the website). Unfortunately, it's not that simple. There are subtle differences between most digital drawings and what the machine is programmed for. We rarely just make a channel program without having the barrel in hand to make sure everything lines up.

Typically, our machinists take the barrel channel diagram and add .040”. From there, we tweak it as needed to get the perfect spacing between the stock and the barrel. But “perfect spacing” is subjective. Some customers want to see a large gap between the stock and the barrel, while others want almost no space.

One final consideration. A #3 contour or a Sendero contour barrel does not mean that every #3 or Sendero has exactly the same dimensions. There are minor variations from barrel manufacturer to barrel manufacturer. This is where a good gunsmith - having all the components in possession - can make small modifications to perfect the fit.

If you have any questions, call us or call your gunsmith. We’re happy to help!